The main qualities we keep readily available are:

Garlock

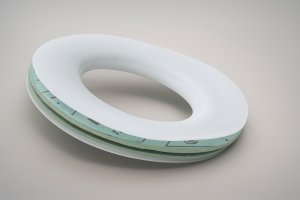

In 1994, Garlock introduced GYLON® Style 3545 for low bolt load applications. It was designed specifically to seal pitted, warped or wavy flanges. Featuring soft, compressible outer layers and a rigid PTFE inner core, Style 3545 is ideal in situations where a rigid gasket is required, such as hard-to-reach piping systems, valves and flanges. The layers of rigid PTFE and microcellular PTFE are sandwiched together using the proprietary GYLON® thermal bonding process, rather than adhesives, for longer gasket life. Style 3545 is so innovative, it received the 1995 Vaaler award from Chemical Processing magazine.

The Garlock family of GYLON® products has evolved over the years with a focus on quality to meet and exceed customer expectations. The use of Employee Involvement, Statistical Process Control, Vendor Assurance Programs, and a continuous improvement philosophy continues to guarantee end users the highest quality products available. Testing is performed regularly on all styles and thicknesses to ensure the consistency of Garlock quality in GYLON® sheets. Quality American-made products, 47 years of experience, on-time delivery and value-added service programs, all are reasons why the GYLON® family of products has become such a major sealing component in industry today.

Gylon 3545: highly compressible microcellular PTFE with a rigid PTFE core for improved handling. The GYLON® 3545 designed to compress and conform to irregular or damaged surfaces, making it suitable for flanges that generate lower compressive stresses, such and glass-lined flanges and equipment. Suitable for strong caustics, strong acids, hydrocarbons, chlorine, cryogenics and glass-lined equipment. Conforms to FDA regulations.

- Tighter seal

- Highly compressible PTFE outer layers seal under low bolt load. Suitable for many flat-face and glass-lined flanges

- Compressible layers conform to irregularities, especially on warped, pitted, or scratched flanges

- Rigid PTFE core reduces cold flow and creep normally associated with conventional PTFE gaskets

- Excellent chemical compatibility. Withstands a wide range of chemicals

- Soft PTFE can be cut easily from larger sheets, reducing inventory costs and expensive downtime

- Rigid PTFE core facilitates installation, especially on large diameter flanges and hard-to-reach areas

- Will not support flame

- Will not support bacterial growth

Gylon 3501-E: The first choice for universal applications in the chemical and petrochemical industries. The combination of high pressure/temperature (P x T) and minimal cold flow far exceeds the performance of conventional PTFE.

- Tight seal

- Improved performance over conventional PTFE

- Reduced product loss and emissions

- Reduced creep relaxation

- Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

- Excellent bolt torque retention

- Withstands a wide range of chemicals for extended service life in a wide variety of applications

- Offers some of the largest sheet sizes in the industry

- Improved material utilization reduces waste

- Branding and color coding reduces misapplication

- Will not support flame

- Will not support bacterial growth

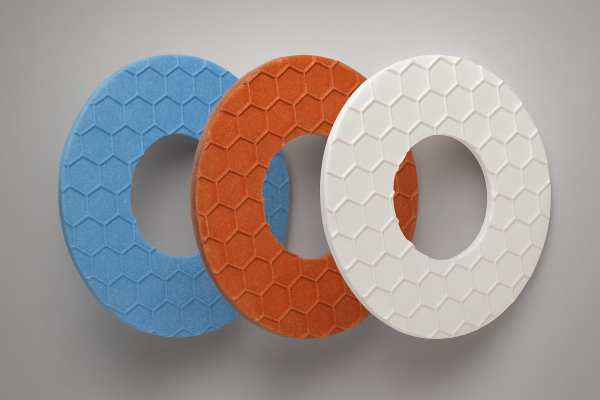

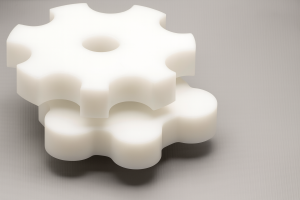

Gylon EPIX 3501-E: EPIX technology will provide superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets that are used in worn and pitted flanges. In addition, GYLON EPIX® delivers the tight sealing and load retention properties of 1/16” (1.6mm) and the conformability of 1/8” (3.2mm). The hexagonal profile provides improved compressibility and recovery. The profiled surface reduces the contact area during initial compression to concentrate the compressive force of the flange for improved sealability.

- One thickness does the job of two

- Seal performance and load retention equal of 1/16” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Patented hex profile creates superb sealing and ability to conform to imperfect flange surfaces

- Same material as traditional GYLON®

Gylon 3510: high performance, barium sulfate filled PTFE gasket material. GYLON® 3510 PTFE gasket is designed for use in strong caustics and toxic chemicals, such as chlorine, ammonia, and phosgene, where initiating and maintaining an extremely tight seal is critical. In addition, the GYLON® 3510 provides exceptional performance in monomer services. Suitable for strong caustics, moderate acids, chlorine, gases, water, steam, hydrocarbons, and cryogenics. Conforms to FDA regulations. Style available for oxygen service as well.

- Tighter seal

- Improved performance over conventional PTFE

- Reduced product loss and emissions

- Reduced creep relaxation

- Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

- Excellent bolt torque retention

- Withstands a wide range of chemicals for extended service life in a wide variety of applications

- Offers some of the largest sheet sizes in the industry

- Improved material utilization reduces waste

- Branding and color coding reduces misapplication

- Will not support flame

- Will not support bacterial growth

Flexitallic

Sigma® 500: High chemical resistance, biaxially orientated PTFE containing hollow glass microspheres. Offers enhanced compressibility for low bolt loads and improved flexibility over conventional calendered and graphite sheets. It is capable of creating a seal across a wide range of gasket stress. This makes the product suitable not just for use in standard metallic flanged connections and also in load compromised bolted connections; such as those applications involving glass lined, plastic and thin or distorted metal flanges. Sigma® 500 material is inherently clean, making it suitable for use in industries where product contamination may be of concern such as food, beverage and pharmaceuticals. Suitable for sealing most chemicals across the whole pH range (0-14) with the exception of molten alkali metals, fluorine gas, hydrogen fluoride or materials which may generate these. Available for Oxygen service.

- FDA Compliance Ideal for food industry, pharmaceuticals or electronics

- WRAS certified for drinking water: Approval No. 1206528

- TA-LUFT approved

- DVGW DIN 3533-6 tested

- USP Plastic Class VI approved

- Cryogenic up to 260ºC (500ºF)

Klinger

- KLINGER® Top-chem 2000 (API 6FA).

- KLINGER® Top-chem 2003

- KLINGER® Top-chem 2005

- KLINGER® Top-chem 2006

- KLINGER® Soft-chem

Belpa

- Belpa Flon PL: Gasket made of pure 100% expanded multidirectional PTFE with high resistance to chemical attack and corrosion for chemical, pharmaceutical and food industry (Complies with FDA homologation). It is made of pure 100% expanded PTFE processed in a manufacturing process that produces a microstructure with a high number of multidirectional oriented fibers. This process confers a great structural uniformity that gives the material the necessary qualities to be used in a wide range of applications. Belpaflon PL is recommended where high resistance to chemical attack and corrosion is required and, in special, for chemical, pharmaceutical and food industry. Approvals FDA 21, CFR 177-1550

- Belpa Flon 9000-LC: Gasket material made of Modified PTFE with specials fillers in order to increase the creep deformation with an excellent chemical resistance, including acids and alkalis at high concentrations in pharmaceutical and food industry. PTFE sheet with an addition of special particles in order to increase the creep deformation resistance. Gasket material with an excellent chemical resistance, including acids and alkalis at high concentrations (sodium hydroxide, sulfuric acid, nitric acid, hydrogen chloride, potassium hydroxide). It is specially designed for services in which the chemical attack is combined with high pressures and temperature, improving on the traditional PTFE sheet's performance. There is an addition of special charges that prevents the creep deformation. Non-flammable and No aging. Approvals FDA 21, CFR 177-1550

- Belpa Flon 9005-LC: Gasket material made of Modified PTFE with specials fillers in order to increase the creep deformation with an excellent chemical resistance, including acids and alkalis at high concentrations for industry. PTFE sheet with an addition of special particles in order to increase the creep deformation resistance. Gasket material with an excellent chemical resistance, including acids and alkalis at high concentrations (sodium hydroxide, sulfuric acid, nitric acid, hydrogen chloride, potassium hydroxide). It is specially designed for services in which the chemical attack is combined with high pressures and temperatures improving on the traditional PTFE sheets. There is an addition of special charges that prevents the creep deformation. Approvals FDA 21, CFR 177-1550

- Belpa Flon 9006-LC: Gasket material made of modified PTFE with specials fillers with an addition of special particles for low bolt load applications. PTFE sheet with an addition of special particles in order to increase the creep deformation resistance, and with a high compressibility, specially recommended for use where a low bolt load applications are required for glass-lines flanges. Gasket material with an excellent chemical resistance, including acids and alkalis at high concentrations (sodium hydroxide, sulfuric acid, nitric acid, hydrogen chloride, potassium hydroxide). It is easy to cut, and it has an excellent assembly and disassembly as its anti-stick properties. Non-flammable and No aging. Specially recommended for glass, plastic and ceramic flanges. Approvals FDA 21, CFR 177-1550

There are countless brands of this material type, though most of them keep the same color code:

- Pink: PTFE modified with silica filler. Especially suitable for alkali and strong acids except hydrofluoric acid. Other applications also include solvents, fuels, water, steam and chlorine.

- Blue: PTFE modified with glass microspheres. Designed for glass pipelines, ceramics or plastics, and irregular flange faces.

- White: Teflon modified with barium sulfate. Perfect for alkali, solvents, fuels, water, steam and chlorine. Particularly suitable for hydrofluoric acid if not pure.